INTRODUCING OUR NEW

FIBER PRODUCTS FOR 2024

Watch Dr. Andy Gillooly, Head of Business Development at Fibercore as he introduces our latest eagerly anticipated specialty optical fiber products innovations for 2024.

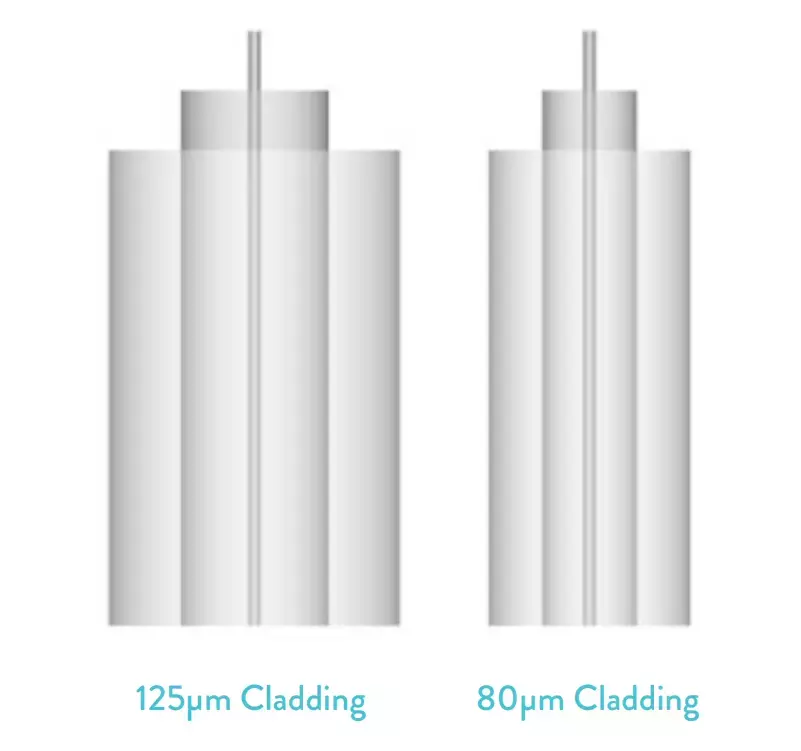

High Absorption Reduced Cladding (HARC) Erbium Doped Fibers

Mini, micro and pluggable QSFP EDFAs require the active fiber to fit within an extremely small coil size. This demands a HARC™ (high absorption reduced cladding) fiber which has a smaller diameter, lower bend loss, higher absorption and is more flexible than standard erbium doped fibers. Fibercore can offer a range of different reduced cladding diameter erbium doped fibers focused on these applications.

For mini, micro and pluggable QSFP EDFAs:

Typical Applications:

Read more about HARC™ Fiber and speak to our experts about your specialist fiber requirements. |  |

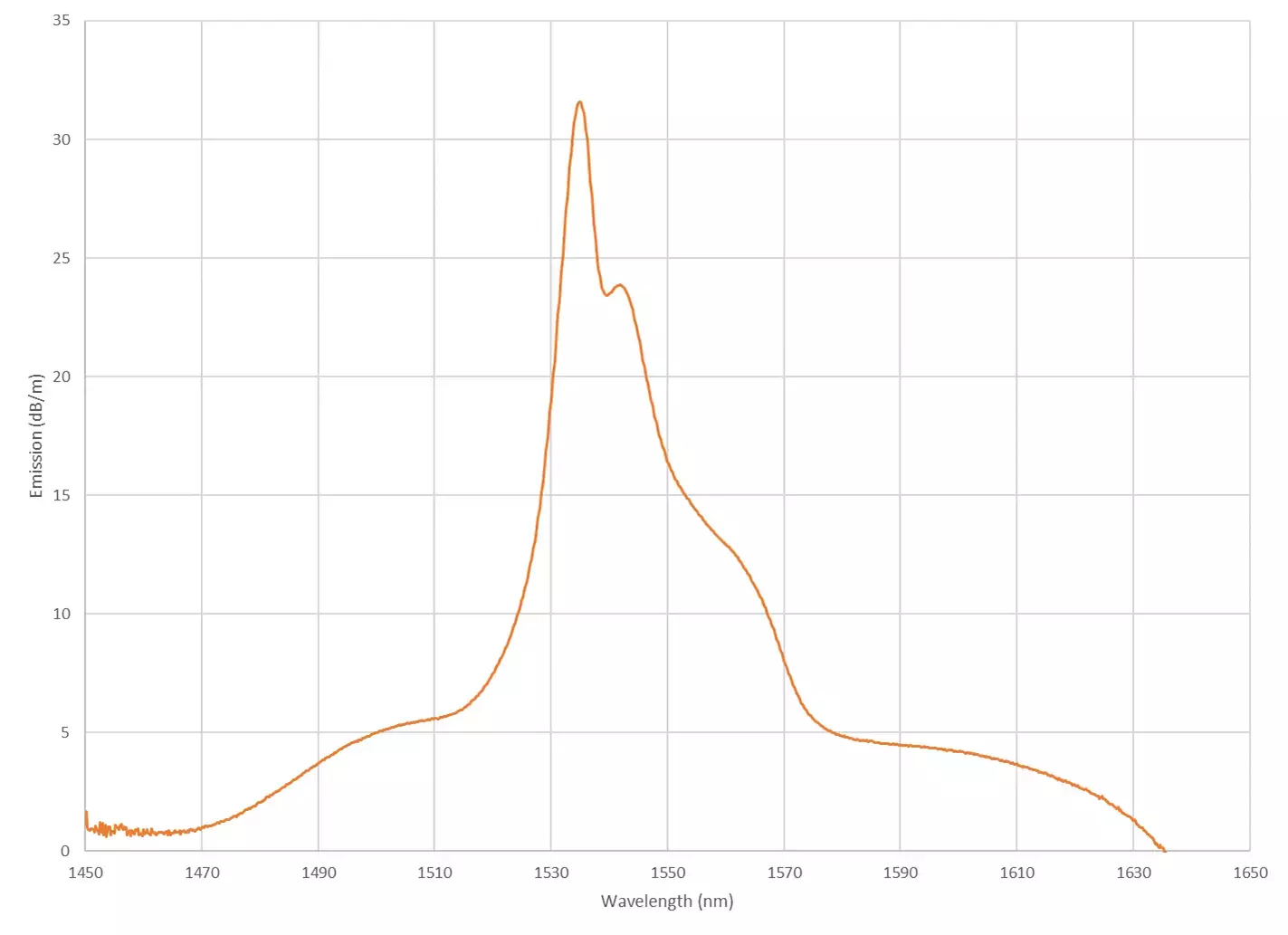

L-Band Erbium Doped Fiber

Fibercore’s L-band Erbium Doped Fiber (EDF) product, L-35(1530/125)HC, offers a pioneering fiber design that provides superior performance for L-band Erbium Doped Fiber Amplifiers (EDFAs). The core composition of L-35(1530/125)HC has been engineered to maximise the gain performance between 1570 nm to 1630 nm and beyond. This allows use of the fiber in L, L+, L++ and Super L-band amplifiers.

Fibercore’s high cut-off wavelength (HC) fibers have larger core diameters, reducing non-linear effects and increasing efficiency at higher pump powers.

Due to high power L-band amplifiers typically requiring long lengths of optical fiber, the fiber has been designed to minimize the total size of the optical fiber required. The coating diameter has been reduced from the industry standard 245μm to 200μm and the core absorption is high. This results in smaller fiber coils with less fiber, ultimately leading to smaller footprint amplifiers.

Typical Applications:

- L-band EDFAs / Telecoms

- Low Power Fiber lasers

- Wide band ASE sources

- Lidar

Read more about L-band Erbium Doped Fiber and speak to our experts about your specialist fiber requirements.

Subscribe for Insights!

Register to receive Fibercore's latest key updates, events and relevant industry news

straight to your inbox!

Speak to our experts

Provide us with your information and our service team will contact you

Dr. Andy Gillooly

Andy Gillooly the business development manager at Fibercore (Southampton, U.K.). In 2001, Andy graduated from the University of Birmingham, with a masters degree in physics and received a PhD in fiber Bragg gratings (FBGs) from Aston University, England. He spent over four years as a senior development engineer at SPI Lasers, developing FBGs and pulsed fiber lasers. After SPI, Andy joined Sharp Laboratories of Europe, responsible for the optical design and technical customer interactions for Sharp's wafer level camera project. Later, Andy joined Fibercore where he is currently responsible for driving the company forward into new markets with new products, he has currently been with Fibercore for 14 years.